Premium Polymer Liners & Components

Torlene® sets the new standard in premium linings used in bulk material handling. Torlene® is recognized as the ultimate solution in bulk solids flow due to it’s exceptional non-stick sliding surface. The low-coefficient of friction and self-lubricating ability of Torlene®, allows work hardening and therefore superior abrasion resistance when compared to other premium liners. Torlene® offers the following advantages:

Material Flow:

-

- The smooth free-flowing surface of Torlene® will eliminate common problems with cohesive material flow bridging and ratholing.

Abrasion Resistance:

-

- Torlene® will outlast materials such as UHMW, Nylon, Teflon, HDPE, and similar materials many times over, due to it’s very dense molecular structure and extremely low coefficient of friction.

Exceptional Dimensional Stability:

-

- The alloyed matrix of Torlene® makes it the most dimensionally stable plastimeric material, resulting in reduced stress failures and superior performance in many bearing applications.

Machinability:

-

- The unique dimensional stability of Torlene®, makes it perfect for the machining of bushings, bearings, and gears.

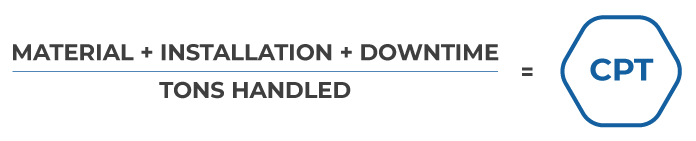

Lowest Cost Per Ton:

-

- Torlene® will substantially reduce your operating cost, when compared to any other lining material. The true Cost Per Ton can be calculated as follows…

Physical Properties

Typ. Values

Test Methods

Physical Properties

Density, g/cm3

Typ. Values

0.94

Test Methods

ASTMD792

Physical Properties

Hardness, Rockwell R Scale

Typ. Values

67

Test Methods

ASTMD785

Physical Properties

Recommended Operating Temperature

Typ. Values

Test Methods

Physical Properties

Maximum Continuous, °F (°CJ

Typ. Values

225(107)

Test Methods

ASTMD638

Physical Properties

Tensile Properties

Typ. Values

Test Methods

Physical Properties

Maximum Strength, psi

Typ. Values

5,200

Test Methods

Physical Properties

-- MPa

Typ. Values

36

Test Methods

Physical Properties

Yield Strength, si

Typ. Values

2,800

Test Methods

Physical Properties

-- MPa

Typ. Values

19

Test Methods

Physical Properties

Elongation at Break, %

Typ. Values

400

Test Methods

Physical Properties

Flexural Modulus, psi

Typ. Values

90,000

Test Methods

ASTMD790

Physical Properties

-- MPa

Typ. Values

622

Test Methods

Physical Properties

IZOD Im act Strength at 23 °C, ft-lbs/in2 (kJ/m2J

Typ. Values

Test Methods

Physical Properties

Notched

Typ. Values

No break

Test Methods

ASTMD256A

Physical Properties

Double Notched

Typ. Values

38(78)

Test Methods

Internal

Physical Properties

Mean Coefficient of Linear Thermal Elfansion er nc

Typ. Values

1.6x 10-4

Test Methods

ASTMD696

Physical Properties

Coefficient of Friction against Polished Steel at 23 °C

Typ. Values

ASTMD1894

Test Methods

Physical Properties

Static

Typ. Values

.10

Test Methods

Physical Properties

Dynamic

Typ. Values

.08

Test Methods

Physical Properties

Abrasion Index

Typ. Values

7.5

Test Methods

Sand Slurry

Physical Properties

Abrasion Index

Typ. Values

9.0

Test Methods

ASTMG65

Physical Properties

Surface Resistivity, ohms

Typ. Values

>10 16

Test Methods

ASTMD257

Physical Properties

Volume Resistivity, ohms-em

Typ. Values

>1016

Test Methods

ASTMD257

Physical Properties

DENSITY, G/CM³

Test Method: ASTM D 792

Typ. Value: 0.94

Hardness, Rockwell R Scale

Test Method: ASTM D 785

Typ. Value: 67

Recommended Operating Temperature

Maximum Continuous, °F (°C)

Typ. Value: 225 (107)

test

Tensile Properties

Test Method: ASTM D 638

Maximum Strength, psi

Typ. Value: 5,200

MPa

Typ. Value: 36

Yield Strength, psi

Typ. Value: 2,800

MPa

Typ. Value: 19

Elongation at Break, %

Typ. Value: 400

FLEXUAL MODULUS, PSI

Test Method: ASTM D 790

Typ. Value: 90,000

MPa

Typ. Value: 622

IZOD IMPACT STRENGTH AT 23°C, FT-LBS/IN² (KJ/M²)

NOTCHED

Test Method: ASTM D 256A

Typ. Value: No Break

DOUBLE NOTCHED

Test Method: Internal

Typ. Value: 38 (78)

MEAN COEFFICIENT OF LINEAR THERMAL EXPANSION PER ∩C

Test Method: ASTM D 696

Typ. Value: 1.6 x 10-4

COEFFICIENT OF FRICTION AGAINST POLISHED STEEL AT 23°C

Test Method: ASTM D 1894

STATIC

Typ. Value: 0.10

DYNAMIC

Typ. Value: 0.08

ABRAISION INDEX

Test Method: SAND SLURRY

Typ. Value: 7.5

ABRAISION INDEX

Test Method: ASTM G 65

Typ. Value: 9.0

SURFACE RESISTIVITY, OHMS

Test Method: ASTM D 257

Typ. Value: >1016

VOLUME RESISTIVITY, OHMS

Test Method: ASTM D 257

Typ. Value: >1016

Call For A Product Consultation

Installation:

-

- As Torlene® only weighs a fraction (approximately 12%) of that of carbon steel, there is no special handling equipment required. Cutting and drilling can be performed with traditional hand held tools. Installation can be done with either weld washers/caps*, capped bolts*, or floor screws. *Used on ½” or thicker

Optional Formulations:

-

- Torlene® is available in Anti-Static and Weldable Versions. It is also available in white for color sensitive mineral processing applications.

There is no comparison!

-

- Equipment owners of bulk material handling equipment such as chutes, hoppers, and drag chain liners would agree, the coefficient of friction is the most important indicator of the total wear performance over time.

- The lower the friction the better the wear resistance.

|

When comparing UHMW Polyethylene to Hudco’s Torlene® the difference offers a remarkable and money saving advantage for you and your company.

**See Product Comparison Chart on the Downloadable PDF