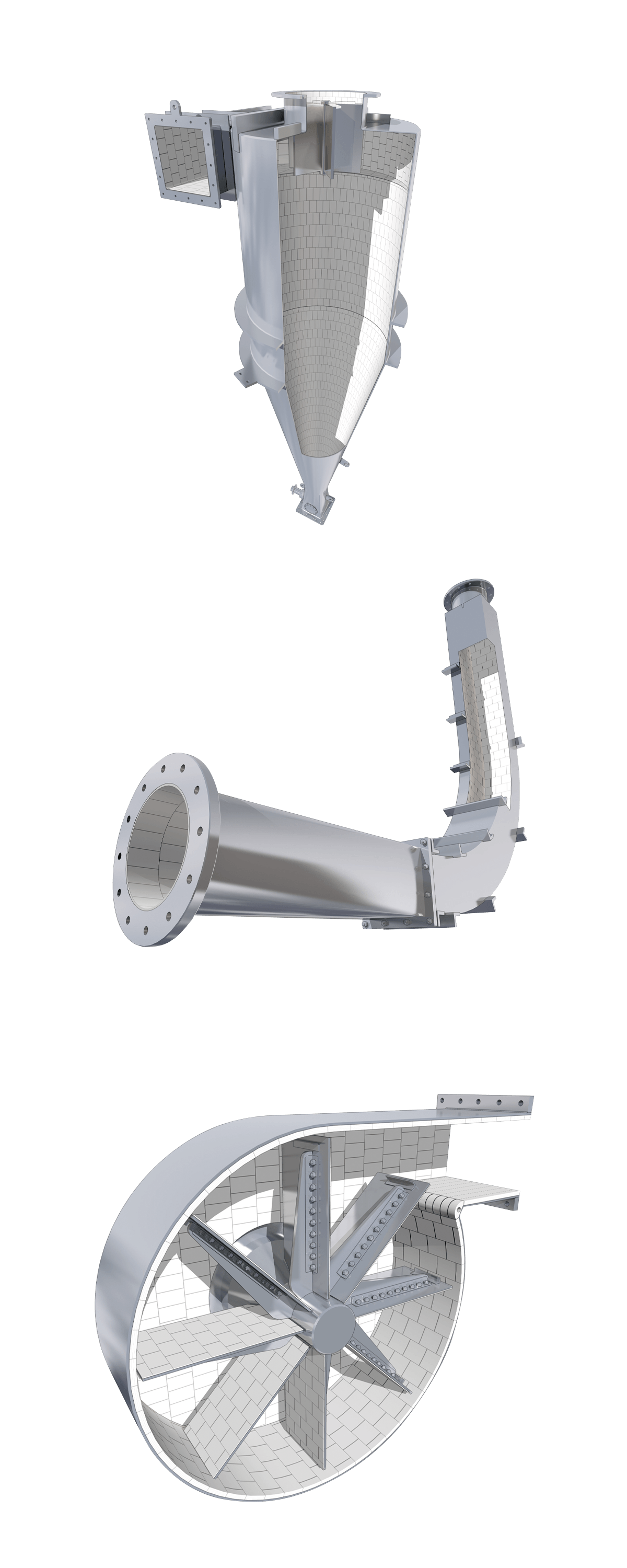

The Ultimate Solution to Severe Abrasion

HUDCO enables you to win the war against severe industrial abrasion with WearLine® , the remarkable technological advancement in wear resistant ceramic tile. Developed and manufactured by HUDCO from years of intensive research and practical in field experience, WearLine® is the only wear resistant material that effectively resists both impact abrasion and sliding abrasion. As a result, WearLine® saves the materials handling industry more maintenance dollars than other wear resistant lining available.

WearLine® is a high density ceramic composed of 90 – 92% microcrystalline alpha alumina and less than 2% silica. WearLine® has the highest density (227.2 Lb/ft3 ) and the lowest residual silica content of any commercially available ceramic tile. In field applications and laboratory tests WearLine® has consistently out performed in both wear and impact resistance. WearLine® is the most effective and economical ceramic tile on the market.

ADVANTAGES

Superior Wear Resistance

WearLine®’s fi ring methods (23 hours longer and 1000°F

higher) are superior to other ceramic tiles giving WearLine

the highest density and best wear characteristics.

High Impact Resistance

3 to 5 times better impact resistance than standard ceramic due

to stronger grain boundaries.

Saves Down Time & Maintenance Costs

WearLine®lasts 3 to 7 times longer than the other ceramics

tile resulting in increased productivity.

Increased Flow Rates

WearLine®polishes in use resulting in decreased friction,

reduced material blockage and increased through put.

Dimensional Stability

WearLine®maintains its exceptional dimensional stability and

resists temperatures up to 2900 without warping or loss of

abrasion resistance.

Low temperature applications

WearLine®’s surface is impervious to moisture preventing

material from freezing and sticking at low temperatures.

Physical Properties for Wearline® High Alumina Ceramic

Alumina Oxide

90 – 92%

Bulk Density

3.52 – 3.6 g/cm3

Young’s Modulus

270 GPa

Vickers Hardness

9 GPa

Shear Modulus

110 GPa

Modulus of Rupture

275 MPa

Compressive Strength

1.77 GPa

Maximum Use Temp

1250°C

Apparent Porosity

0%

Physical Properties for Wearline® High Alumina Ceramic

ALUMINA OXIDE

- 90 – 92%

BULK DENSITY

- 3.52 – 3.6 G/CM3

YOUNG’S MODULUS

- 20°C

-

- 270 GPA

VICKERS HARDNESS

- 20°C

-

- 9 GPA

SHEAR MODULUS

- 20°C

- 110 GPA

MODULUS OF RUPTURE

- RT

- 275 MPA

COMPRESSIVE STRENGTH

- 20°C

- 1.77 GPA

MAXIMUM USE TEMP

- 1250°C

APPARENT POROSITY

- 0%

Physical Properties for Wearline® 96 High Alumina Ceramic

Alumina Oxide

96%

Bulk Density

3.72 g/cm3

Flexural Strength

358 MPa (psi x 10^3)

Elastic Modulus

9 GPa (psi x 10^6)

Hardness

78 R45N

Fracture Toughness

4.5 MPa m^1/2

Compressive Strength

2068 MPa (psi x 10^3)

Maximum Use Temp

1250°C

Apparent Porosity

0%

Physical Properties for Wearline® 96 High Alumina Ceramic

ALUMINA OXIDE

- 96%

BULK DENSITY

- 3.72 G/CM3

FLEXURAL STRENGTH

- 20°C

- 358 MPA (PSI X 10^3)

ELASTIC MODULUS

- 20°C

- 9 GPA (PSI X 10^6)

HARDNESS

- 11.5 GPa (kg/mm2)

- 78 R45N

FRACTURE TOUGHNESS

- 4.5 MPA M^1/2

COMPRESSIVE STRENGTH

- 2068 MPA (PSI X 10^3)

MAXIMUM USE TEMP

- 1250°C

APPARENT POROSITY

- 0%